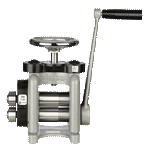

Jewelry Rolling Mill Machine and Tools

A jeweler’s work shed isn’t complete if it does not have a jewelry rolling mill. Whether you are attempting pattern imprinting, rolling the metal into a wire, or thinning the metal, a quality rolling mill is necessary if you are to produce high-grade jewelry.

What is a jewelry rolling mill?

A jewelry rolling mill is a very useful tool for a jeweler. While the primary use of a jewelry rolling mill is to thin wire and sheet metal, a jewelry rolling mill is suitable for a range of other tasks such as imprinting patterns and textures to metal, fold forming, rolling thin gold foil, or making tapers on wire.

How to clean a rolling mill machine jewelry?

If unmaintained, a rolling mill machine jewelry can become rusted over time – as is the case with all steel tools. To prevent rust, use D-40, a wooden dowel, and sandpaper of either 600 or 1000 git.

If you are using oil, make sure that the machine is oiled only when not in use. You must also be sure to remove all oil traces before operating the machine.

Types of jewellery rolling mill machine rollers

A jewellery rolling mill machine has 4 different rollers; full round, flat, wire, and combination.

- A jewellery rolling mill machine with a flat roller helps create imprints in the metal and reduce the thickness of sheet

- Wire rollers roll and reduce the diameter of the wire

- Combination rollers have both flat and groovy surfaces. They are convenient but are not as wide as a flat roller

What is best for jewellery rolling mill tools?

Jewelers generally prefer a combination mill when it comes to choosing jewellery rolling mill tools. As noted above, they would need to sacrifice width for this.

Best practices for using a rolling mill for jewelry making

Keep in mind the following tips when using a rolling mill.

- Dry metal: Using damp metal increases the chances of risk pitting and will cause marks on the roller

- Roll gradually so that you don’t crack the piece when annealing

- The machine must be oiled and maintained if you are to use it for a long time

- Use acetone and a damp cloth to erase marks and remove dirt from the roller. If there are stubborn blemishes, use fine steel wool and wet and dry paper.

- Cover the mill when it is not in use so it is not exposed to debris

What is an electric jewelry rolling mill?

If you are looking to take the burden of physical labor off you and make work flow more efficient, you can’t go wrong with an electric jewelry rolling mill.

The downside? It is significantly more expensive than a manual mill.

What is a hand rolling mill jewelry?

With a hand rolling mill jewelry, the user will need to manually turn the rollers to operate the machine. For most craftsman, the capabilities of a hand rolling mill jewelry should be enough.

How to use a jewelry rolling mill ?

A jewelry rolling mill is common in every jeweler’s workshop. The machine is quite similar to a mangle in many ways. Traditionally, a rolling mill came with steel rollers so that when metal passed through the rollers, it was compressed. This either changed the gauge or sometimes the shape. When cutting the thickness by half, the craftsman must double the length – if the rolling is done in a single direction. The rolling process should be gradual and the compression will make sure that the metal works harder. Because of this, the metal must be annealed in between each rolling stage.

Other than rolling sheet, a rolling mill machine has other capabilities such as being able to roll wires to a D shape or square section. This is important when a craftsman is trying to create a shaped or tapered effect. For a home work shed or a smaller professional workshop, a smaller rolling mill is better. You can find larger automated mills with advanced features but they are generally recommended for workshops with large floor space. This is because all rolling mills must be secured to the floor – sometimes with a dedicated bolted stand.