Silver Solder Types for Jewelry

Many jewelers think ofmetal-making at their first torch soldering involvement. That fluctuating silver flash when the solder begins to flow is magical. However, what is actually occurring at that moment? What are the silver solder types? What is the art behind soldering?

What is Silver Solder?

Usually, silver solder contains:

- 65% fine silver.

- 20% copper.

- 15% zinc.

So, it sounds like. Solder that is made from sterling silver instead of lead. It is used for soldering sterling silver, so you have a standardized piece of metal. If you were to use lead solder (or any other type of solder), the finished item would look odd where the solder was applied.

Silver solder types

4 different types of silver solder:

- Sheet solder –You need to cut your own chips of solder.

- Wire solder –Which is the thing that you like to use.

- Chip solder –It’s already in small chips.

- Paste solder –A motion plus solder blends.

It doesn't matter what measure of wire, sheet, or chip solder you get. You just cut the volume you want for the soldering ended.

These are the best 4 types of soldering tools;

1. Torches

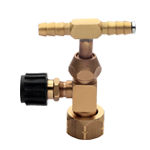

- Mini Gas Regulator

- Eco Tray Torch

- Gas Hose 8 mm

- Hose Clamp 8 mm

- Brass T 3

- Hydrazone Torch

- Hydrazone Torch Pins

- Hydrazone Air Tube 6 mm

- Blue Air Tube 8 mm

- Transparent Air Tube

- Plastic Air T

- MT Burner 3938

- MT Boyun 70 mm

- MT Şalümo Başlığı 2941

We have a huge collection of Torches solders. You can visit our store to see more.

2. Boards

- Honeycomb Soldering Board Big

- Soldering Block with Feet

- Soft Boldering Block

- White Soldering Block

- Hard Soldering Block

- Metal Soldering Sieve

- Ring Soldering Ceramic Stand

- Ceramik Mandrel

- Rotary Table Square Soldering Block

For further details, visit our store.

3. Solders

- Silver Sheet Solder

- Dado Welding Wire

- Micro Miniature Stake Set of 14

4. Chemicals

- Flux Soldering Powder 0.5 kg

- Flux Powder 1 kg

- Soldering Liquid Transparent 1 lt

- Soldering Liquid Transparent 5 lt

- Yellow Soldering Liquid 1 lt

- Hydrazone Inside Solution

- Hydrazone Outside Solution

- Technoflux Fire Protection

- Borax Container Ceramic

For more selection, follow the link.

How to Choose a Silver Solder?

The initial step in choosing a solder is to select what metals will be attached because the type of metal used will significantly influence the type of silver solder used. Soft solders are frequently used with copper, tin, and brass. These solders have a low melting point and are made of tin and lead.

So, it is good if you need a visible closureof the added silver volume in the solder. Therefore, choose the hard solder (75% pure silver) instead ofthe soft solder with minor silver volume. This will slow down the tarnishing on that layer.

How to Solder Jewelry?

Do you need soldering? Here you will learn various methods. Each kind has its own effectiveness, depending on the current task. We are listed below the 4basic methods used although soldering:

-

1.Standard soldering

It is a frequently used method. Lay your solder chip, wire, or sheet over the join and heat with a torch whichever from the top or below.

-

2.Pick soldering

The great heat saver of your piece until the end. Most goldsmiths like this method while accomplishing delicate work, for example, chain joins, design wire, and difficult to arrive at areas.

Lay a bit of solder on your board, heat it until it folds into a ball, and then get it with your soldering pick. Saving your heat ready of solder, move it to the join and hold it there toward the finish of the pick until it streams right where you need it to go.

-

3.Fluid soldering

When you are joining two pieces, this is a good technique to control your solder flow. Put a-bit on your soldering board. Place solder down on it, then heat it until the solder melts. You will remove the heat quickly (you need to look at that spot where the solder melts yet has not arrived at the streaming point).

Flip the piece over onto the following one, solder side among the two. The heat from the top or below until the solder streams, guarantee to warm the entire piece you need it soldered to.

-

Stick soldering

Save your wire solder whole, heat the wire's finish, and let the solder movementalthough moving the wire stay to the parts that need soldering. This method needs an actual flame, and if not, you will have closed using far more solder than required.