All About Jeweler's Saw | Choosing the Right Saw Blades

Finer blades are easier to use but move more slowly. Coarser blades remove a wider path but cut faster. The best rule of thumb for determining blade thickness is to choose the right saw blades with 2 or more teeth for the thickness of the metal to be sawed. If you use a coarser blade with fewer teeth, it will fasten and become difficult to use. The number of teeth on a blade indicates the speed with which it will cut.

Jeweler Saw Blade Sizes and Information

Choose the right saw blade that is suitable for the size and shape of the cutting material. The ideal ratio of the materials is three teeth. Use a B and S gauge to determine the unknown thickness.

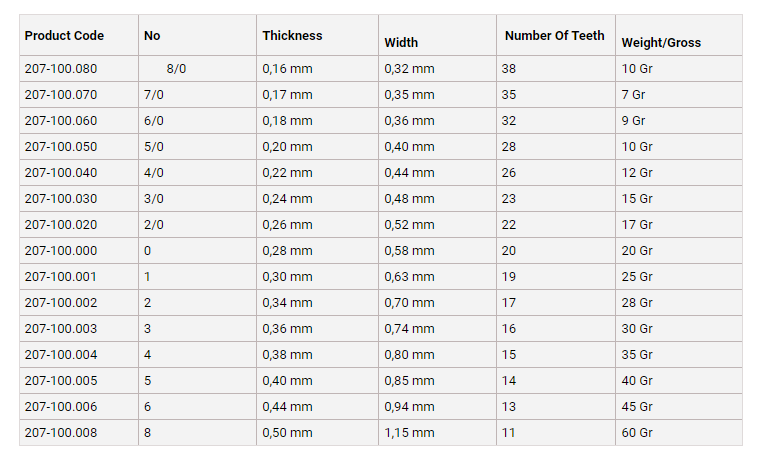

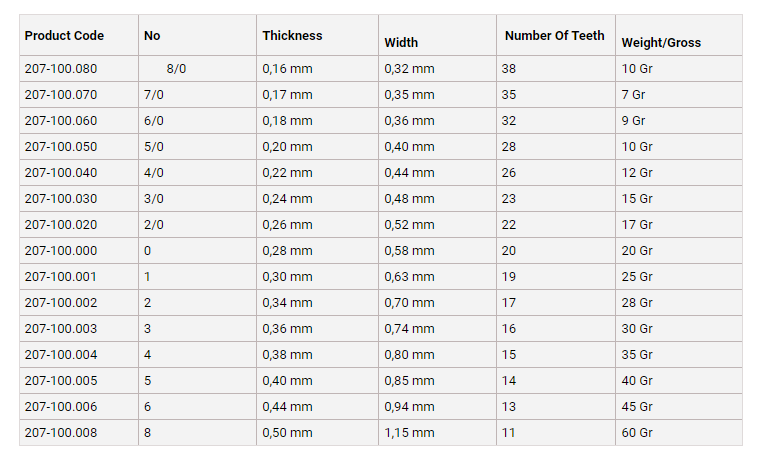

Saw Blades Size Chart:

For further information about jeweler saw blades size visit our website.

Which Saw Blade(S) Should I Use?

When sawing in a straight line, you typically need a thicker blade; you'd choose a finer blade to see a curve or fretwork. You'll change yours saw blade regularly, depending on your needs. Choose the right saw blade based on the number of 'teeth' per cm. Fine blades have more teeth per cm than coarser blades, so the finish is finer. Traditionally, the thickness of the metal you use is around 2 teeth. Also, consider the type of metal you use when choosing a saw blade, as some metals are harder than others. So for silver, while typically choosing a 2/0 blade, for gold and platinum, starting with a 3/0 blade. Some saw blades are sold in bundles of at least 12, so you may want to buy multiple bundles, so you always have plenty to hand when they break (which they do frequently) while working.

Check out our best jeweler saw and saw blades collection.

How to Use Your Saw?

Typically, you would use your saw with the piece supported by a wooden bench pin clamped to your jeweler’s bench. Normally, the bench pin will have two V-shaped cutouts to allow different shapes to be pierced out and allow the piece or the saw to rotate during piercing. Generally, you would begin cutting metal, wax, or Perspex from the edge of the metal or a pre-drilled hole. It would be best if you primarily used yours saw in a completely vertical position, sawing in a soothing up and down motion. The saw only cuts in a downward direction.

Choosing the Right Size Blades

Choosing the right size blade for the material thickness to see. If yours saw blade of jewelry is too big for the metal, it will catch and grab, and if the saw blade is too small, it will be ineffective and will dull quickly. Saw blades don't cut. They weaken, chip away small metal particles. If you look closely at the blades' teeth, you'll see they alternate in a predictable pattern called a set. This arrangement allows metal chips to fall on both sides of the blade. The distance from the correct teeth' outer point and the left teeth' outer point is blade thickness.

Take the speculation from choosing the saw blades with Alex Machine's "Jeweler Saw Blade Sizes and Information" chart. This chart shows you the most common blade sizes' dimensions with the drill sizes of the equivalent jeweler and recommended material thickness range. Print this FREE resource and post quickly in your work area.

Things consider when you are choosing the right size blades:

- Jeweler's blades are scale-sized. Considering size 0 (zero) as the middle of the scale, larger saw blades are numbered: #1, #2, #3 etc.

- The higher the number of blades, the larger the blade. Smaller blades are numbered: 1/0, 2/0, 3/0. The higher the blade saw, the smaller the blade.

A good thumb rule is three (3) metal-thick teeth. If the sheet of metal is thicker, the blade will be coarser. If you cut many straight lines, bigger blades work well, and smaller sizes are better for curved cutouts. Thinner blades may be more accurate but break easier.

Stringing the Jeweler's Saw

After choosing the jeweler's right size saw blade, it's time to string in the saw frame of the jeweler's saw blade. The saw blade teeth should be facing you and down, so slightly hitting the jeweler saw blade would catch your finger and indicate the tooth's direction. The idea is to cut the jeweler's saw blade by pulling, not pushing.

It's important to realize that saw blades will break. An efficient sawing technique, the right size blades, and beeswax lubricant can all help reduce breakage.

- Lose the wire around the saw blades, remove the jeweler's saw blade, and then twist the wire back around the remaining blades.

- Hold the handle and apply steady pressure to the frame end against the table without bending the jeweler's saw frame.

- Since the blades in the jeweler's screw-frame are slightly extended, insert first the blade-end close to the handle and stiffen it as if it was stringing an arching bow. Be sure that the teeth point to the handle.

- Add the blade's far end into the frame, slightly tighten and release pressure on the edge of the table or desk.

- Strengthen the far end firmly.

- Readjust the frame to the table and push on the handle more strongly.

- If you get a dense or flat note, release the wing vent on the far end, reposition the blade and tighten up the wing vent. Repeat until you hear a nice sound.

Sawing

- Do not push the saw blade against the metal when the jeweler saw is used because it will catch and potentially break the blade. Allow the blade to work with gentle up and down movement to cut the metal.

- Draw the pattern or shape you're cutting out onto the metal being cut with a marker. You can also use rubber cement to adhere paper with your desired design to cut.

- Drill a tiny hole in the metal area being sawn out, then thread the hole onto yours saw blade before inserting the second end of the blade into the frame if you're cutting out a hole in the center section of a piece of metal.

- To assist in getting the blade engaged, notch the metal slightly. Make a small notch on the metal's edge with a jeweler's file.

- Place the metal on the bench pin that is part of the bench pin system. Place your non-dominant hand's fingers on the metal, stabilize it, and carry the area to be cut first. To lubricate the saw blade, run it across a block of beeswax. Hold the saw frame so that the blade is vertical or slightly pitched forward at an angle to the metal being cut—the position is up to you. Insert the blade into the filed notch and begin moving the blade up and down, utilizing the entire length of the blade.

- Continue sawing around the metal until the shape is cut free. The metal edges should be smoothed out with a file and then polished.

Jeweler's Saws Continued

Jump rings are also made with jeweler's saws. Wind wire around a mandrel and cut apart with a jeweler's saw. "Making Jump rings with Jump Ring Mandrels." To efficiently estimate the amount of wire required, consult the chart titled "Wire Lengths to Make 100 Jump rings."

Sawing Safety and Comfort

When sawing, wear safety glasses because blades can break, and you'll remember yourself getting closer to your work. It's a good idea to take little breaks, use proper lighting, and position your sawing station at a comfortable height for you.

Visit our online store for a jewelry design sawing collection, including basic, intricate, and pierced metal sawn shapes.

Which Saw to Choose

The most challenging decision you will experience is deciding which saw to buy, as there are many options! The following are the main saws available in our jewelry store:

1. Basic Adjustable Jewelers Saw

Most jewelers will begin with a basic adjustable 3” stainless steel jewelers saw. These saws are affordable and can be adjusted using small screws to use longer or shorter saw blades. Because screws can loosen over time, you may need to use parallel pliers to tighten them securely.

- This saw is frequently found in beginner's tool kits.

You can also consider quick release basic saw frames, which are not adjustable so that you can reuse broken saw blades but may be easier to use if you have limited hand strength.

2. Eclipse Saw Frame

The Eclipse Saw Frame is popular among jewelers. This is a fixed steel saw frame with a wooden handle, so it is not adjustable, and the company that makes them has been in business for many years. Years. These frames are usually of excellent quality and long last.

3. Swiss Grobet Saw Frame Fixed

This is another frame that is popular among jewelers because it is made of lightweight metal and affordable. It has a rubber handle, and screw locks to secure and tighten the blades, unlike the basic or Eclipse models.

4. Knew Concepts

The most modern Knew Concepts Saw was introduced in 2008. The frames are made of lighter metals such as aluminum or titanium, have a lattice style frame that adds to the saw's lightness, and use magnetic new tech. Knew concept saws are lighter to use, making them a good choice if you plan on doing a lot of sawing or fretwork. The original model has a screw tension mechanism, but the most popular version has a quick-release mechanism, and some models even have a blade swivel mechanism.

5. Green Lion Saw

The Green Lion Saw is a more recent addition to the jeweler's saw lineup. It's a sleek, almost sculptural saw frame made of a flexible steel frame and a rubber handle. It is noticeably heavier than the Knew Concepts Saw, but it is both beautiful and well-balanced for sawing. It has a fixed frame and cannot be adjusted to accommodate different saw blade sizes, so it is not the first choice for sawing large pieces of metal, but it is a joy to use for smaller pieces.

What to consider when buying a saw frame?

When choosing the right saw, keep the following factors in mind:

Depth of the Frame

You'll need to think about the typical size of the pieces you're making. The saw frame depth determines how metal sheet you can cut and shape before the back of the saw hits the metal when you turn it around. If you plan on sawing heavy pieces, search for a saw frame with a 5 deep saw frame as this will reduce the amount of time you have to stop and start sawing.

Handle Size

Handles were made of wood, but modern models have rubber handles. If you want a lot of sawing, you might want to consider a rubber-handled saw, which will be more comfortable to use. However, if you only saw on occasion, you can get away with a wooden handle.

What is the Saw Handle Made of?

Further, you want to think about what the saw is made of. Steel frames are often heavier than lighter metals such as aluminum frames, so you might want to make a lightweight frame for comfort if you plan much sawing.

How You Fasten the Blade?

You may need what's best to use, and if you're struggling with strength or flexibility, you may want to look at a quick-release saw frame or something like the Knew Concepts that don't require tension or force. But whatever you've chosen, remember it's just a tool. If you don't have a robust sawing technique, you'll struggle to make the most of it. So we suggested starting with a basic saw to learn and practice with and upgrade further down the line once you feel the kind of saw that will best serve you.