How you Select a Rolling Mill for Jewelry Making | 5 Ways to Use Your Rolling Mill

How Do You Select A Rolling Mill For Jewelry Making?

Do you need to buy a rolling mill? Here are some suggestions for selecting and buying one and the different features you may want to look out A good rolling mill for jewelry making will save time and money and boost your productivity, and increase what you can do and make. So, a high-quality rolling mill for jewelry making will be an investment in your business. But what makes a good quality mill?

We offer the best quality rolling mill for jewelry making, and you can visit our online shop.

- Features like brass bushes reduce the risk of jamming.

- Case hardened rollers ensure toughness and longevity.

- New flexible frames offer incredible strength with a certain amount of steel flexibility, giving the perfect combination of strength without delicacy.

- The finishes, styling, and attention to detail are all things that define Machines brand.

Our rolling mills are designed to perform regularly and give expected, reliable service for many years. With so many models to select from, where do you start? Check it out.

- 1.Durston TUI Single Motor Cylinder 130 mm Click Here.

- 2.Durston Mini Single Motor Cylinder 130 Mm Click Here.

- 3.Durston Arm Mini Cylinder Combined 100mm MINIC100 Click Here.

- 4.Durston Single Motor Cylinder 130 mm Click Here.

- 5.Durston Arm Reducer Combined Cylinder 130 Mm Click Here.

- 6.Durston Tui Double Motor Cylinder 130 Mm Click Here.

- 7.Durston Sleeve Reducer Cylinder Liner 130 mm Click Here.

- 8.Durston Double Motorized Cylinder 100 mm Click Here.

- 9.Durston Agile Ailindir Combined 130 Mm Click Here.

- 10.Durston Double Motor Cylinder 130 Mm Click Here.

- 11.Durston Arm Reducer Combined Cylinder 150 mm Click Here.

- 12.Durston Mega Foot Cylinder 130 mm Click Here.

- 13.Sleeve Cylinder Economic Combined Click Here.

- 14.Durston Mega Foot Roller 160 Click Here.

- 15.Lever Cylinder Economic Wire Click Here.

- 16.Cylinder Stand Double Click Here.

- 17.Sleeve Cylinder Economic Liner Click Here.

- 18.Lever Cylinder 7 Roll Click Here.

- 19.Best Silikone Spray Click Here.

- 20.Durston Standard Cylinder Stand Click Here.

- 21.Durston Cupboard Cylinder Stand Click Here.

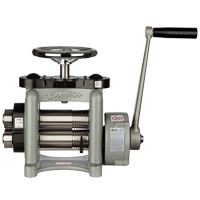

Manual vs. Electric

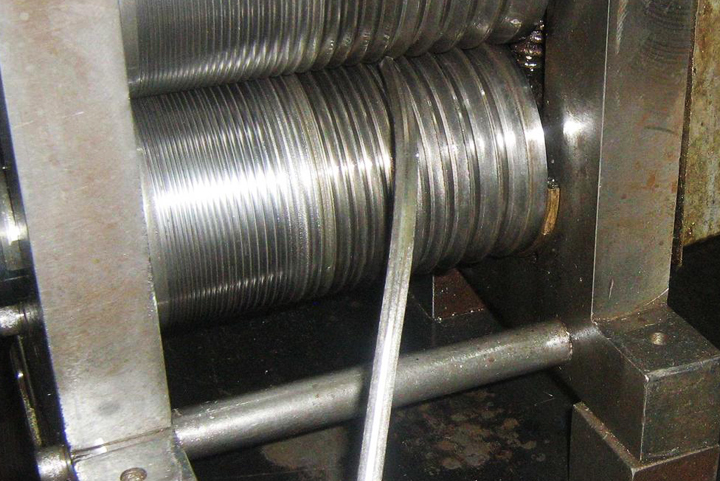

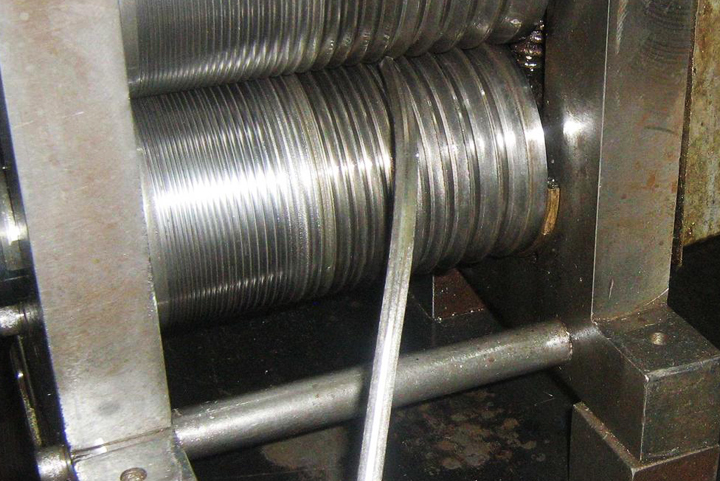

Jeweler’s rolling mill is a machine involving two very smooth, highly polished, cynical steel rollers, mounted in a strong, rigid structure.

|

Manual rolling mills |

Electric rolling mills |

|

· Normally, Jewelers are equipped with a manual rolling mill. · Jewelers are making production more efficient. ·Cost-effective, so for jewelers, a manual jewelry rolling mill is appropriate. |

· Electric mills are available and are frequently required for larger production companies. · The electric rolling mill will do most of the physical labor for you but work speedily. · Little expensive, costs significantly more than a manual mill. |

Gear Ratio and Reduction Gears

Manual rolling mills are offered with or without a gearbox.

With gearbox

- The gear-reduction box houses gear increase hand-power.

- They are providing more force with less effort.

- Decreases the amount of physical effort necessary to feed metal through the mill and reduces your body's pressure.

- The rolling handle must be rotated more times to turn the rollers.

- It needs far less force, allowing the gears to do the heavy work.

Without gearbox

- A rolling mill without a gearbox, also known as a direct-drive manual mill.

- It needs more power-force to turn the handle and roll metal.

- Though direct rolling need only one rotation of the handle for the rollers to complete a full rotation.

- They require considerably more strength.

Ratio

Average gear ratios for reduction gear rolling mills are listed as 6:1, 5:1, 4:1, etc. A rolling mill with a 6:1 ratio requires six turns of the handle for the rolls to finish a single rotation. With the gearbox, the rolling handle must be rotated more times to turn the rollers. Without a gearbox, need only one rotation of the rollers' handle to complete a full rotation, but need more force.

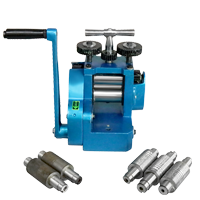

Types of Rollers

For Jewelry making, we have presented different types of rollers. It depends on your needs, you can select from flat rollers, wire rollers, or a combination rolling mill with flat and wire rollers.

Most jewelers prefer a combination of rolling mills because they work with different materials.

- 1.Flat rollers for jewelry making

These rollers are utilized for rolling out and decreasing the thickness of sheet metal. Flat rollers work efficiently to imprint patterns and textures into the metal with a “roller printing technique.” Pretty organic and botanical forms can also be made in sheet metal with a “fold forming technique.”

- 2.Wire rollersfor jewelry making

Wire rollers are used to reducing the diameter of the wire. These rollers will roll the wire into a chamfered square cross-section. A wire can be drawn down into a smaller gauge or tapered to a graceful point much more quickly and efficiently than by hand forging.

- 3.Full round rollersfor jewelry making

These rollers are used for rolling out wire but will roll it in a round cross-section. Full round rollers will create a full round wire. These rollers can also be used to reduce the diameter of the round wire.

- 4.Combination millsfor jewelry making

The combination rolling mill offers both a flat surface for sheet metal and a section with grooves on the rolling wire rollers. These rollers typically sacrifice some width for the convenience of having both wire grooves and flat rolling space on the same roller, except in the case of double combination rolling mills, which offer two separate sets of rollers, one flat and one fluted for the wire.

Extension Rollers

There are some rolling mills for jewelry making that come with extensions that permit extra rollers to be included on the mill's side. These extensions;

- Boost flexibility

- They are allowing the rolling mill to be modified as needed.

- Can be purchased in varying shapes, including half-round and many decorative patterns

Extension rollers are perfect for jewelers who work with flat or wire rollers most of the time. As well, they want more width but still occasionally want to work with different rollers.

In this way, width is not sacrificed on the flat rollers for a wire section that will only see occasional use.

Opening Width

When selecting a rolling mill for jewelry making, opening width is an important factor.

- It makes the distance between the rollers when the rolling mill is completely open.

- Determines the hardness of the sheet or wire that can be rolled through the rolling mill.

- So if you plan to roll out ingots or thick stock, you should select a rolling mill with a large opening width.

- Money-saver and make most of the materials you purchase.

Our advanced rolling mills for jewelry making with a reduction gear will be much suitable for this task than rolling mills without reducing gear. As we mentioned above, reduction gear provides more force with less physical effort, allowing fewer passes through the rolling mill with a greater thickness reduction.

Roller Width and Diameter

Roller width another vital feature when selecting a rolling mill for jewelry making. The width of the rollers mill will determine the maximum width of the sheet metal piece. It can be passed through the rolling mill, or for a wire roller, how many trenches there will be to decrease the wire's size.

Alex. Machines offer jewelry making rolling mills with widths ranging from 100mm to 160mm wide. They added flexibility with more wire milling grooves or a great surface capacity for flat milling. The diameter of the rollers is a great feature to consider when buying a rolling mill. Superior rollers make less curve that will form in the metal during rolling. So any curve-shaped while rolling is simple to accurate.

Quality vs. Price

A rolling mill for jewelry making is a major investment that a jeweler should hope to make only once during their career. When buying a rolling mill, focus on;

- Your primary needs.

- It will boost your mechanical growth.

- Proper care and maintenance, keep the quality rolling mills, and price with the longer warranty.

- The quality rollers are made from high-quality, hardened steel. They guaranteed even rolling with a lower risk of scrapes or dents and a lifetime of reliable service.

Durston brand rolling mills are papular for their accuracy, consistency

, and strength, the best rolling mills in the jewelry industry. Durston rolling mills are best designed to be the workhorse of professional jewelry.

- It is made from the highest quality apparatuses.

- Including high-quality induction-cynical steel rollers.

- Have cast iron frames for strength and stiffness.

- Have self-oiling and care-free bearings.

So selecting a price saving rolling mill is a decision that will help you and your jewelry business succeed. Look at the complete selection of rolling mills for jewelry making with worldwide shipping offered from Alex. Machines.

5 Ways to use your Rolling Mill

Most jewelers use their rolling mills to imprint patterns on an annealed metal sheet. Others use a rolling mill as the raw material workhorse of their workplaces.

1. Rolling mills – Harden Your Steel Metal

The primary use of rolling mills is to roll a metal sheet into a thinner sheet. It will also work-harden it. So you can buy smaller gauge metal, but what if you want a gauge that’s not readily available? Most jewelers like to use 23-gauge metal. However, they reduce the heavier measure sheet to the right size for him using the rolling mill.

2. Stamp Patterns on Sheet Metal

The main explanation we utilized for our workplace rolling mill was to run metal sheets through it. It was enjoyable to engrave designs onto the toughened copper sheet. I would rapidly have designs on a copper metal sheet that was ready to sell. Leaves, blossoms, twigs, and delicate screening materials would all be able to be utilized. Continuously build up the metal that you need to stamp on. Using our rolling mill for jewelry making in this limit is heaps of fun and very fulfilling. So, there's quite a lot more it can do.

3. Melt and Roll Scrap Into Usable Sheet

When I start my jewelry business, I realized how significant a rolling mill is, and I learned to appreciate it. It was the first occasion that I ever saw scrap metal melted into an ingot. Next, I looked as Alex ran that ingot through a rolling mill until he smoothed it into the gauge he needed. This is the thing that he does with his scrap metal. Instead of sending it off for cash, if he needs a measure and doesn't have it available, he melts and rolls it. It will be a money-saver when jewelers melt scrap into ingots and roll them through the rolling mill. This makes your own metal sheet or wire from scraps. Our quality rolling mill is used to turn metal sheets or scrap into thinner pieces, turning a piece of gold into a thin foil for making jewelry.

4. Fold Forming

For fold forming, they will do quick work. It can help make shriller, crispier edges on your folds. Using the rolling mill makes it easier to complete your work efficiently. Folding metal with our efficient rolling mill will give you the best result, what you want.

5. Rolling Mill With Dual Adjusting Screws or Knobs

The rolling mill has dual-adjusting screws or knobs that can get out of adjustment. To set them, tighten both down, back off by turning equally at once. A quarter turns at a time until they are where you need them to be. Whether your rolling mill has two adjusters or one, it can create twisted or warped metal when it’s out of adjustment.

6. Roller printing –Use the rolling mill safely.

You can find objects with commercial texture plates. You can print textures onto metal using a rolling mill, also called roller printing. It can damage your mill and if you don't use it safely. This unlocks a new space of creativity when it comes to working with metal. The metal needs to be annealed before you continue. If you keep hardening the metal with more passes, it could crack. Make sure to follow the advice to avoid damaging your metal. So I highly recommend using a rolling mill for jewelry making; pick a permanent marker to mark on the handle to note which way to turn it. Don’t waste time turning it in the wrong direction." This one step can save you from future issues.