Micrometer Working Principle | How to Use Micrometer

Alexmachine.com has a large selection of micrometers. We make it possible for you to get some of our stock's best and most specific varieties available at competitive prices.

Micrometer Working Principle

A predetermined distance separates the threads of a standard screw. Thread separation equals the distance traveled by a screw in a reciprocating motion. Pitch refers to the distance between a screw's threads. Pitch is typically 1 or 0.5 microns thick. The micrometer works by transforming rotational data into a linear parameter. As a result, the number of rotations and the quantity of axial movement are directly connected.

Micrometer working principles are as follows:

- Pitch of the screw:

The distance the spindle travels per revolution is known as the pitch.

- Least Count of the screw:

The spindle travels one division of circular scale when the least count of the screw is reached in a thimble.

- Zero Error and Zero Correction:

When they come into contact, there should be no difference between the anvil and the spindle's zero and the linear scale's reference line. It is referred to as a zero error micrometer. Positive zero mistakesoccur when the zero of the circular scale is lower than the reference line. This value should be deducted from the final measurement of the sample.

What is Micrometer?

A micrometer is an instrument used to take measurements that require high accuracy than a caliper can achieve. However, they boast advanced precision because they can only measure a minimal distance, so they aren't ideal for determining the dimensions of large objects.

Different Typesof Micrometers

Different digital and mechanical micrometers are available, and others are based on their intended use. The most common applications are caliper gauges for measuring internal bore diameters, external dimensions (like shafts and holes), or determining rolling surface wear.

1. Angle Micrometer

These determine the angle between two planes.

2. Micrometer with Blades

This gauges the o-narrow ring's groove.

3. A ball-end micrometer

Any time an anvil is required to be placed against a rounded surface, it is used to determine the distance between a hole and the surface's edge.

4. Micrometer Bore Gage

Using a Bore Gage, you can determine the diameter of a hole or cylinder.

5. Depth Micrometer

These instruments are used to gauge the exact height of a solid object.

6. Outside Micrometers

To find out how big something is, use this.

7. Micrometer with Pitch Diameter

Screw thread pitch diameter is measured using one of these.

8. The Tube Micrometer

A tube's thickness can be determined using this type of gauge.

How Do Micrometers Work?

Because these instruments are so simple to use, taking measurements with one of them is not a difficult task. Accurate readings can be obtained with the proper use and precautions, ensuring that high-quality products are consistently produced. Generally, the number of threads per inch (TPI) measures how far a screw turn goes into the barrel. Except in a few industries, the 100 TPI caliper is the most commonly used metric caliper.

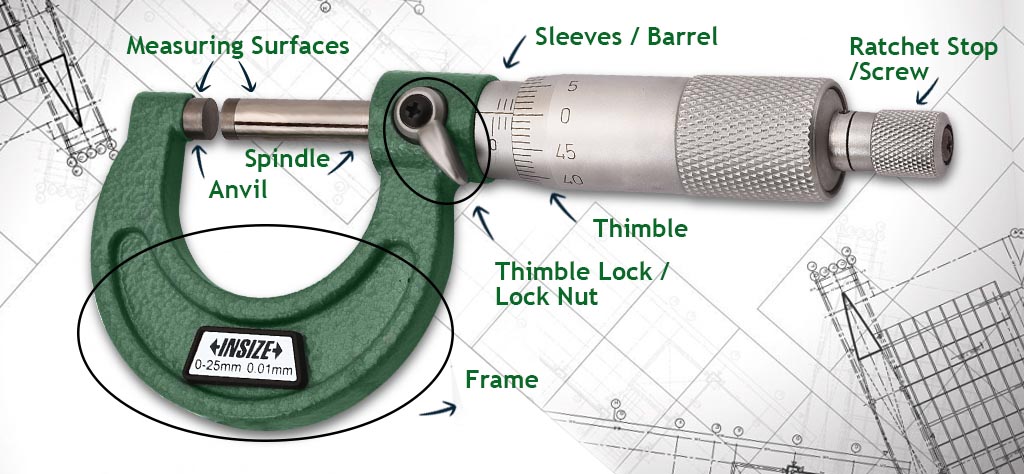

Micrometer Parts and Uses

The frame, anvil, sleeves, locknut, screw, spindle, thimble, and ratchet stop are components of a micrometer.

1. Frame

The C-shaped body joins the anvil and barrel, which is the frame. Under mechanical and thermal stress, this frame is remarkably resistant to strain because of its substantial mass and thickness.

2. Anvil

The anvil is on the frame's right side. This allows the spindle to grip and measure the thing.

3. Sleeves/Barrel

The barrel, or sleeves, holds the anvil on the other side of the frame.

4. Thimble Lock/Lock Nut

The thimble lock, also known as a lock nut, is the lever used to prevent the spindle from moving while the measurement is being taken.

5. Screw

For these instruments to work, a screw is essential.

6. Spindle

When you turn the thimble, it rotates the cylindrical spindle. This grasps the object being measured and holds it firmly in place.

7. Thimble

The spindle moves when the thimble, which is rotated by the thumbs, is turned.

8. Ratchet Stop

Instruments with ratchet stop ensure that only an appropriate amount of pressure is exerted on an object.

Operating Principle of Micrometer

A micrometer's basic operating principle is as follows:

- The rotational movement of a screw can be used to determine its axial movement accuracy.

- This is because the screw's pitch remains constant throughout the assembly process.

- Due to rotation, the screw's actual axial movement has been magnified somehow.

When is a Micrometer Used?

- Engineering and mechanics are the most common areas in which micrometers are used.

- Piston production is one of the industries where this is used because a small error in the dimensions might lead to parts that don't fit.

- A micrometer is used to measure the precise dimensions of hardware components such as pipes and bearings to ensure maximum performance.

- In the past, manual micrometers had to cope with many differences, but now digital micrometers are on the market. Because these may be paired with other hardware instruments, precise measurements can be taken effortlessly.

Care and Proper Use of a Micrometer

- Open the locking lever before turning the thimble or the ratchet. Before taking measurements, use a clean cloth to wipe down the measuring faces.

- Rotate the ratchet knob as soon as you begin taking the readings (not the thimble). The ratchet knob prevents you from overtightening the thimble, which could damage the instrument and give an incorrect reading.

- When the micrometer function is at its lowest reading, the horizontal line on the sleeve should be aligned to zero. The instrument needs to be calibrated if this does not occur. A half-moon adjusting wrench is included with each device for calibration.

- While the micrometer still holds the object, use the thimble lock to secure it. Follow these steps to avoid the spindle from moving while taking the reading or removing the object from the micrometer.

- It's also good to keep the instrument out of direct sunlight for as long as possible.

Things to Remember

- Toto measure tiny quantities; a micrometer is necessary.

- It has a resolution of 0.001 to 0.005 micrometers and can detect particles as small as 0.01 micrometers.

- The screw is referred to as the "heart" of the micrometer because the thread of the screw is critical to the micrometer's ability to measure a given object.

- The screw's axial movement is directly proportional to the number of rotations in the micrometer.

Measure with Micrometers from Alex Machine

Measure with micrometers from Alex Machine, have extensive knowledge of the materials, characteristics, and performance of micrometers for you to get the most out of the machine selection process. Choose high-quality product lines suitable for each specific metal but with diverse functional characteristics. This will give you the most excellent choice. So, when shopping for micrometers, you can choose from a wide selection oftypes, ensuring that you get everything you need and even more. There are various micrometer working principlesavailable these days, but how can we select the best?

Always check the quality before measuring whichever object you measure. Don't settle for something you're not genuinely passionate about. Don't accept anything less than the best. We will keep our customers informed of the most recent advances in this highly competitive sector and production. The most modern types of micrometers will be made accessible to you to help you improve your performance in the jewelry production and processing industry. We make it possible for you to save a significant amount of money by providing several options to match your specific demands and budget. If you require a large quantity of these items, you may place a bulk order. The products are eco-friendly and include a bunch of extras.

FAQ:

What is the use of a micrometer explaining its working?

A micrometer is used for more exact measurements than a caliper can provide. Because they are so accurate, they aren't the ideal choice for measuring massive objects.

What is the principle of a micrometer screw gauge?

The basic principle is: A screw's axial movement can be measured using rotational movement because the screw's pitch does not vary.

What are a micrometer and its applications?

The diameter, thickness, and length of solid objects can all be accurately measured using a micrometer.

What is the working principle outside a micrometer?

A micrometer works like a screwdriver, with a nut on the end. Thimble, the barrel-like structure used to gauge an object's distance, can be rotated axially with this device.

What material is a micrometer?

Carbide is commonly used to coat the anvil and spindle of micrometers to decrease wear from repeated use. It is common to practice to employ hardened steel as the measurement face to save money during manufacture.